| TRANSFORMERS Technical data |

| |

| Dry-Type Transformer |

| Dry-Type Transformer uses insulating paper with strong heat-resistance and moisture tolerance. Impregnated with quality varnish, this product has less risk of fire and features simple

maintenance and easy treatment. It can be produced variously from a small size to a large one. |

| |

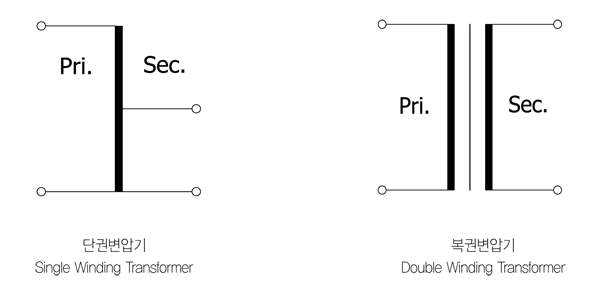

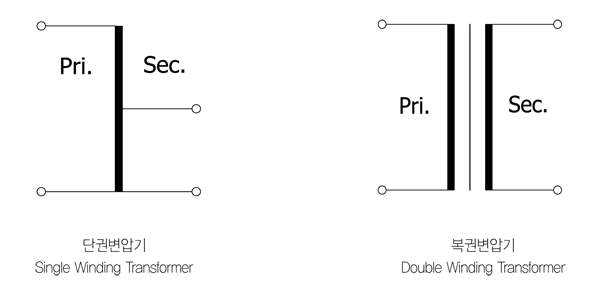

| Single Winding Transformer and Double Winding Transformer |

| Single Winding Transformer |

| Transformer with common circuit of primary winding and secondary winding |

| |

| Double Winding Transformer |

| Transformer with completely electrical separation of primary winding and secondary winding |

| |

|

| |

| Reference Value of Allowable Temperature Rise |

|

| Items |

|

Max Allowable Temperature of Insulating

Material

(℃) |

|

Temperature Rise (K) |

|

Winding

(Temperature rise by resistance measurement method) |

|

105(A) |

|

60 |

|

|

|

|

|

120(E) |

|

75 |

|

|

|

|

|

130(B) |

|

80 |

|

|

|

|

|

155(F) |

|

100 |

|

|

|

|

|

180(H) |

|

125 |

|

|

|

|

|

200 |

|

135 |

|

|

|

|

|

220 |

|

150 |

|

|

|

|

|

| Iron core, metal parts and neighboring materials |

|

|

|

Temperature should not damage iron core, other parts,

or neighboring materials. |

|

|

※ KS C 4311에 근거

※ Based on KS C 4311 |

| |

| Power Frequency Withstand Voltage and Lightning Impulse Withstanding Voltage Values |

|

| Max System Voltage (Effective Value) |

|

Applied Voltage Test (Effective Value) |

|

Impulse Withstanding Voltage (Peak Value) |

|

| (kV) |

|

| 1 |

|

2 |

|

| ≤1.1 |

|

3 |

|

- |

|

- |

|

|

|

|

|

| 3.6 |

|

10 |

|

20 |

|

40 |

|

|

|

|

|

| 7.2 |

|

20 |

|

40 |

|

60 |

|

|

|

|

|

| 24 |

|

50 |

|

95 |

|

125 |

|

|

NOTE : in case of the application of lightning impulse withstanding voltage, a double file is applied to close or open types of dry transformer, and a single file is applied to other types of dry transformers.

※ KS C 4311에 근거

※ Based on KS C 4311 |

| |

| Instruction Manual (Dry-Type Transformer) |

|

Attention!! |

|

Before transportation & installation, make sure to read this manual for right use.

Check the functions, use methods, and safety rules described in this manual before use. |

|

|

|

| |

| For safety use, follow the instructions to prevent electric shocks, failures, and accidents. |

|

| |

Make sure to use the transformer with in its rated capacity. There is the danger of electric shock at current flow, and therefore, neither come close to it nor touch it.

The transfer that is at current flow or stops right before can have a high temperature. Therefore, be careful not to touch it mistakenly or carelessly. Otherwise, it is possible to cause a burn.

To lift the transformer, make sure to use eye bolts.

There is the concern of conduction. Therefore, do not tilt the transformer more than 15˚.

If the transformer needs to be touched for reason of installation and maintenance, be careful not to be hurt by the corners or protruding parts of metals or insulating materials.

If the transformer is damaged or deformed, do not use it.

This transformer is available indoor only. Keep it away from direct rays and rainwater.

This transformer is a self-cooled type product. Therefore, it needs sufficient ventilation (insufficient ventilation may cause overheating).

This transformer has no functions of short circuit and overload protection. Therefore, to use the product, it is required to have sufficient protection coordination.

Do not remodel this transformer.

If this transformer has someting abnormal, power it off immediately, find causes, and come up with measures.

|

|

| |

| 1. Use Conditions |

| |

Altitude : less than 1000m

Ambient temperature : -5℃(-10℃) ~ 40℃ / the temperature in ()

Relative humidity : 45% ~ 80RH

Surroundings : a place without dust, smoke, corrosive gas, vapor, and salt

Frequency : use a designated frequency.

Input voltage waveform : use sine waves as most as possible. |

|

| |

| 2. Attention for Installation |

| |

To move the transformer, use a crane as most as possible. In this case, be careful not to operate the crane with a run.

If this product is hung with a wire, pay delicate attention in order not to cause deformation and damage. Regarding hanging angles, set a wire length in order to make wire angles more than 60˚ from the top of the case. During installation, do not put your foot on the transformer.

When working on the top or around the transformer, be careful not to get dust, metal powders, and impurities caught.

To fix or install the transformer, use all given attachment holes.

If there is some time before operation, come up with measures for dustproof and dew condensation.

Tighten the screws of input and output terminals with given connection torque. |

|

| |

|

| Nominal diameter of bolt and nut (mm) |

|

Recommended connection torque (N.m) |

|

| M3.5 |

|

0.8 ~ 1.0 |

|

| M4 |

|

1.2 ~ 1.4 |

|

| M4.5 |

|

1.5 ~ 1.8 |

|

| M5 |

|

2.0 ~ 2.5 |

|

| M6 |

|

4.0 ~ 4.9 |

|

| M8 |

|

8.9 ~ 10.8 |

|

| M10 |

|

18 ~ 23 |

|

| M12 |

|

31 ~ 39 |

|

| M14 |

|

51 ~ 61 |

|

|

|

| |

| 3. Protection |

| |

A transformer is able to have inrush current several to 20 times higher than rated current because of power supply timing (phase of residual voltage). Therefore, if a protective device installed in the primary side is selected incorrectly, wrong operation makes it impossible to supply power.

As the secondary short-circuit protection of a transformer, a fuse or a circuit breaker for wire is installed on the primary side. If a fuse is used, select delay element type ; if a circuit breaker is used, select extension block type. In consideration of the efficiency and inrush current of a transformer, select a rating in reference to the following fomula. |

|

| |

| |

Rated Current(A) = 1.2 ~ 2 X Rated Capacity(VA) ÷ Primary Voltage(V) |

|

|

| |

① If the primary voltage of three-phase (1Ø) 5kVA transformer is 440V,

Rated current of circuit breaker(A) = 1.5 X 5000(VA) ÷ 440(V) = 17A

(→ Circuit breaker 20A)

② If the primary voltage of single-phase (3Ø) 10kVA transformer is 440V,

Rated current of circuit breaker (A) = 1.5 X 10000(VA) ÷ (440V X √3) = 19.7A

(→ Circuit breaker 20A) |

|

| |

| 4. Repair & Maintenance |

| |

For repair and maintenance, power off the product and ground the main circuit. There is the risk of electric shock.

Right after powering off, do not touch the handle of the iron core. There is the risk of a burn. |

|

| |

| 5. Disposal Instructions |

| |

To dispose of this product, treat it as industrial waste.

Disassembly should be performed only by a skillful worker. There is the risk of injuries. |

|

| |